Project Overview

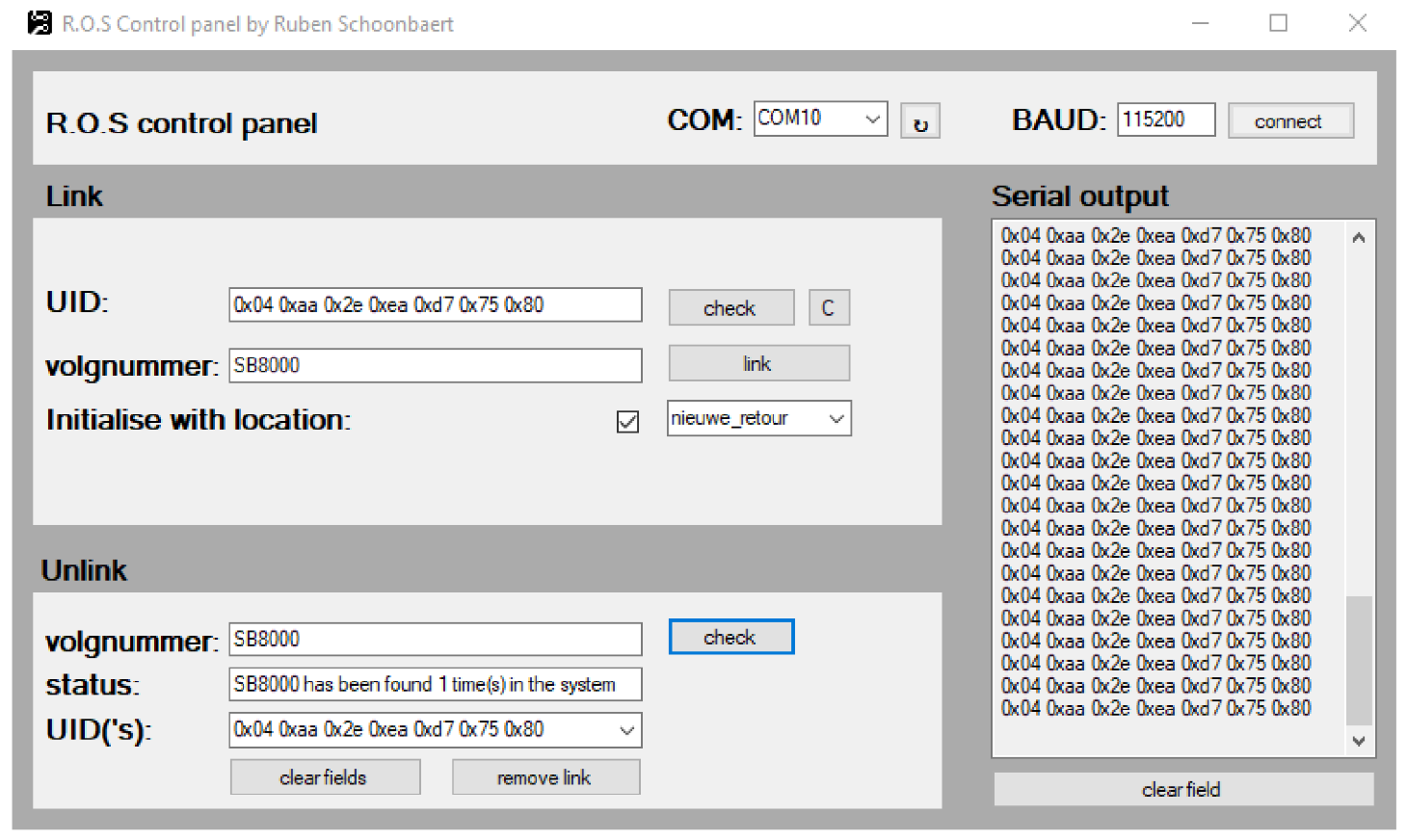

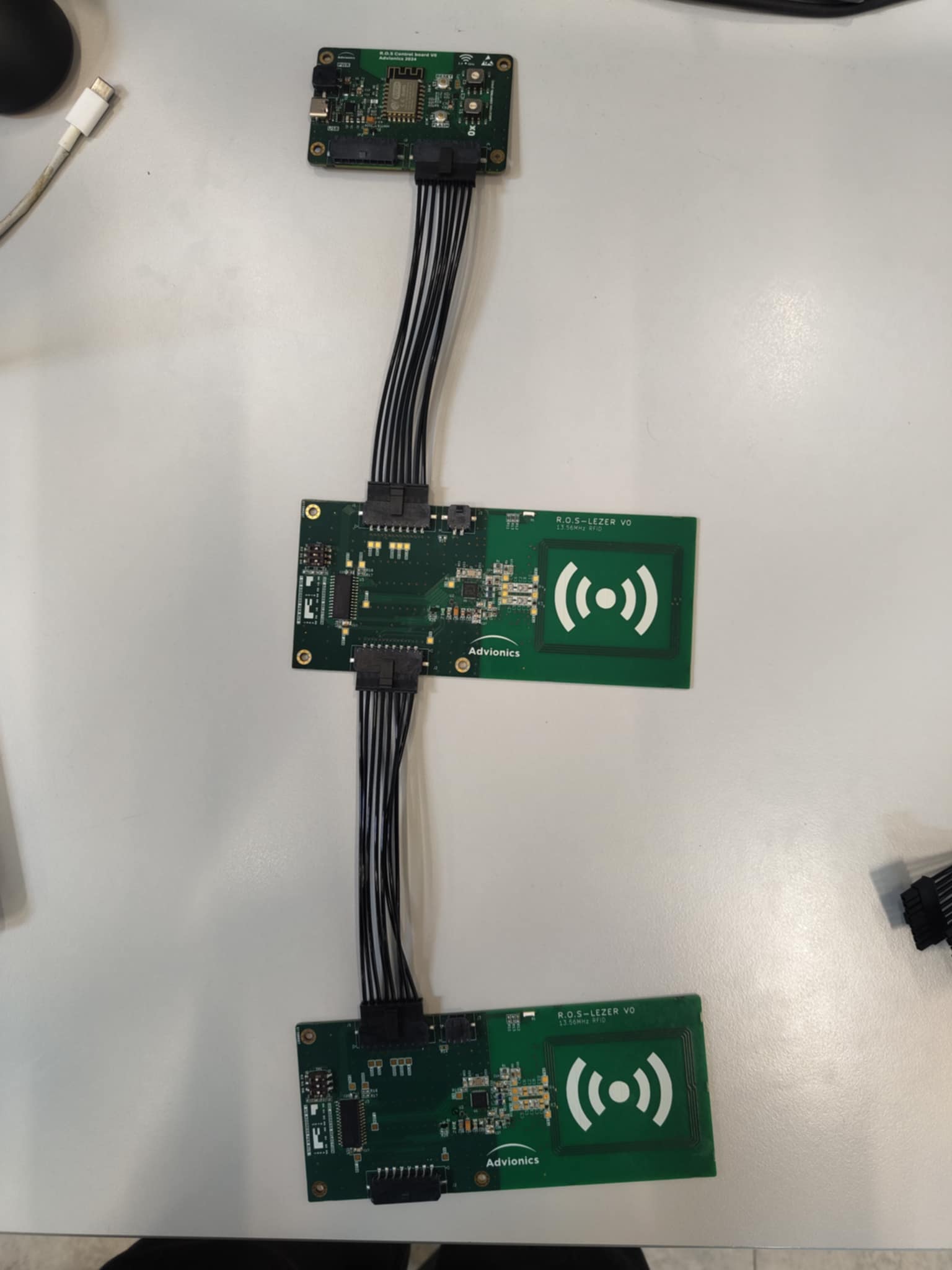

This project focuses on developing an automated digital tracking system that replaces the inefficient manual process of locating returned or work-in-progress components in a production environment. Each tracked unit is fitted with a small NFC tag that contains a unique hardware ID (UID). When placed in a specific work area or storage bin, the tag is detected by an NFC reader module. These readers continuously scan for nearby tags and send the identification data to a Wi-Fi–enabled control board. The control module collects data from multiple readers, adds a predefined location ID, and transmits the information to a central server.

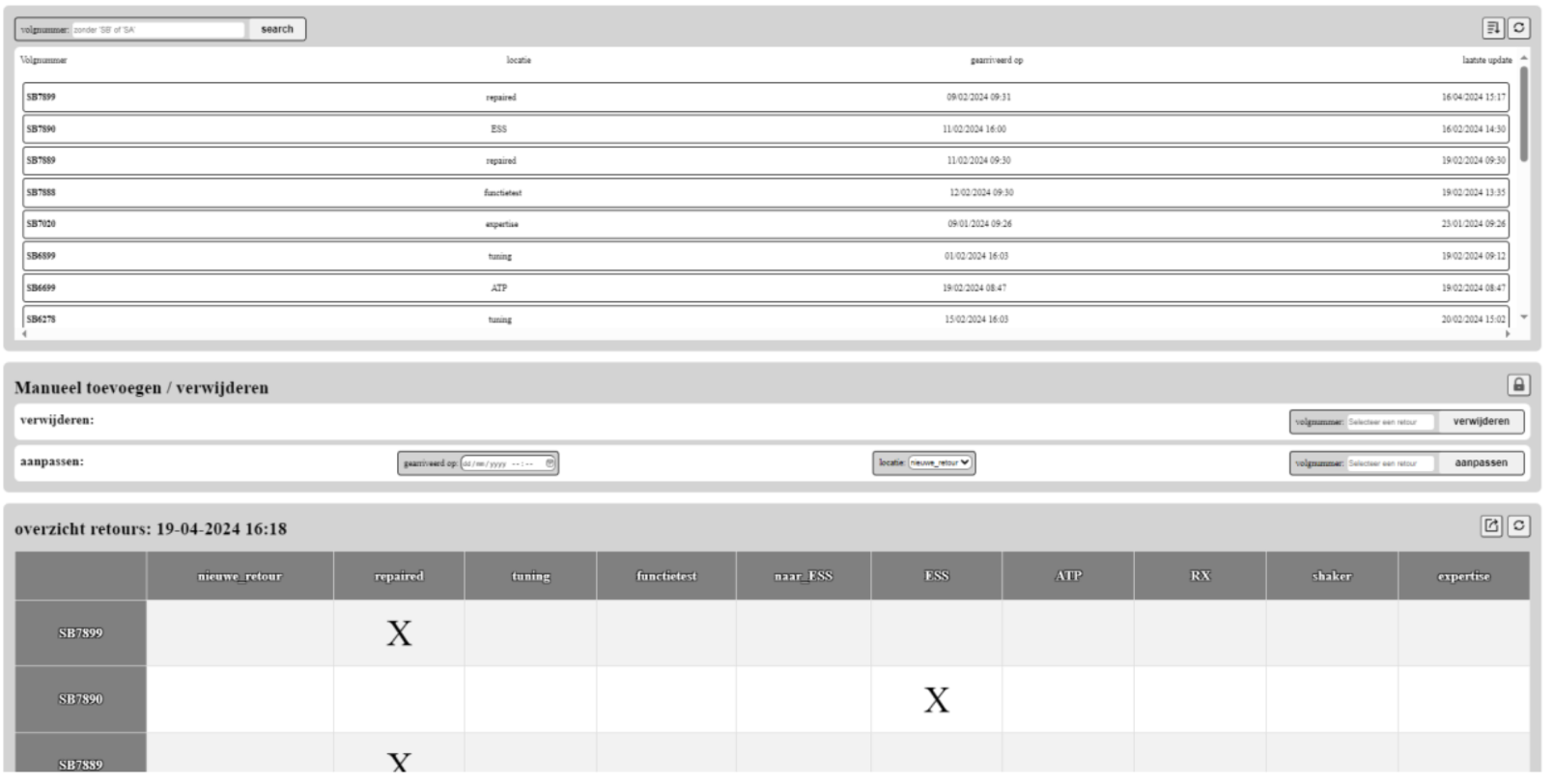

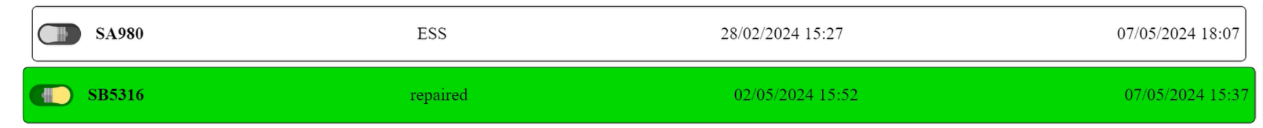

All incoming data is stored in a MySQL database and visualized through a web-based interface accessible from any device on the local network. Operators can instantly search for a specific item using its serial or follow number, view its current location, and monitor its movement history. For quick on-site identification, the web interface includes an LED “locate” feature — activating a visual indicator on the reader module associated with the selected item. This provides an intuitive and efficient way to find items within a complex workspace, reducing time loss and human error.

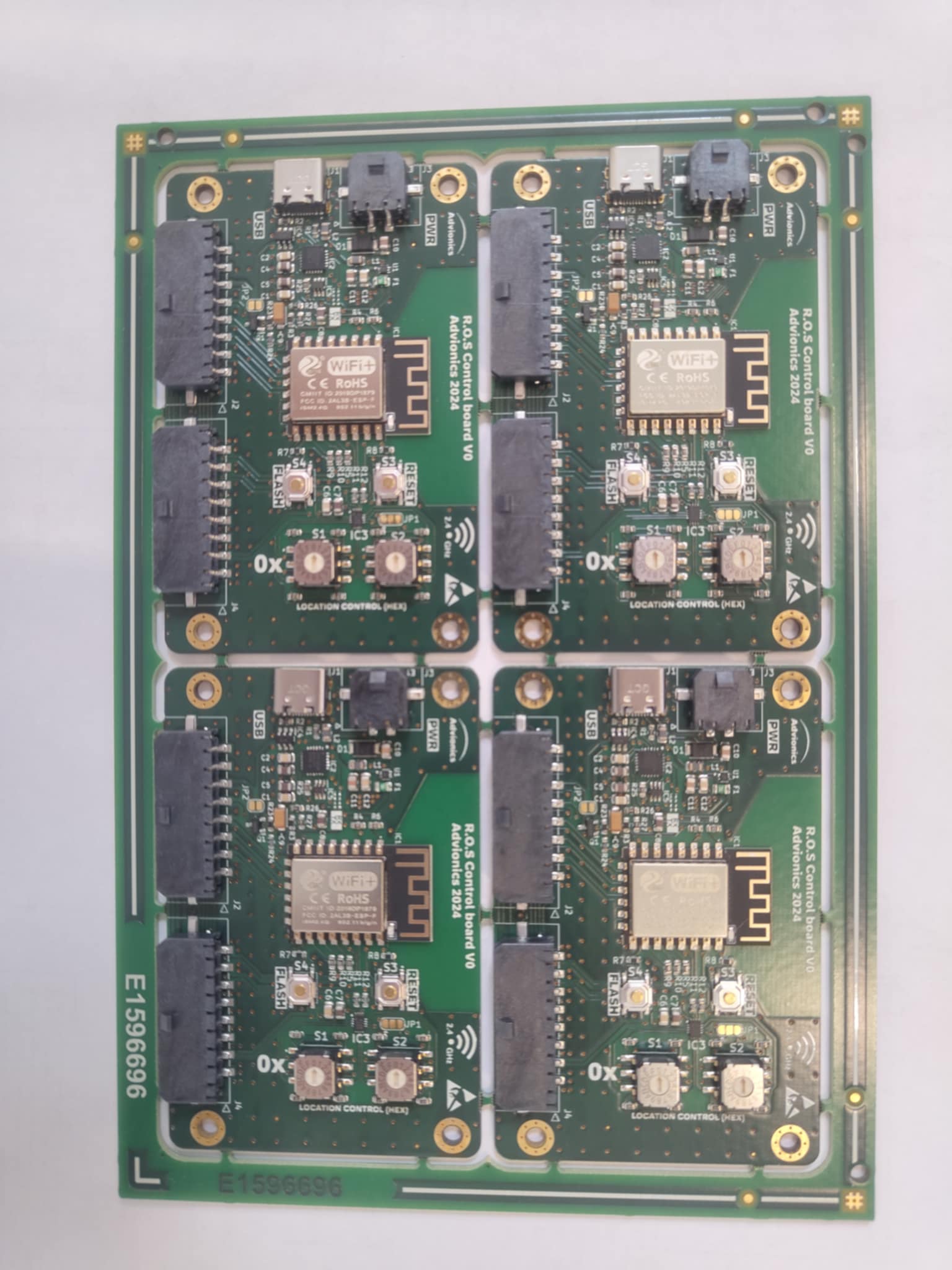

The system’s modular design makes it scalable and adaptable to different workspace sizes. Each control module can handle up to eight NFC readers connected via a shared SPI bus, keeping costs and power consumption low. All modules are built as custom-designed PCBs, programmed in C++ and designed for plug-and-play integration with minimal setup. A Raspberry Pi hosts the backend server, web interface, and database, simulating a production-ready environment for testing and future deployment.

System Architecture

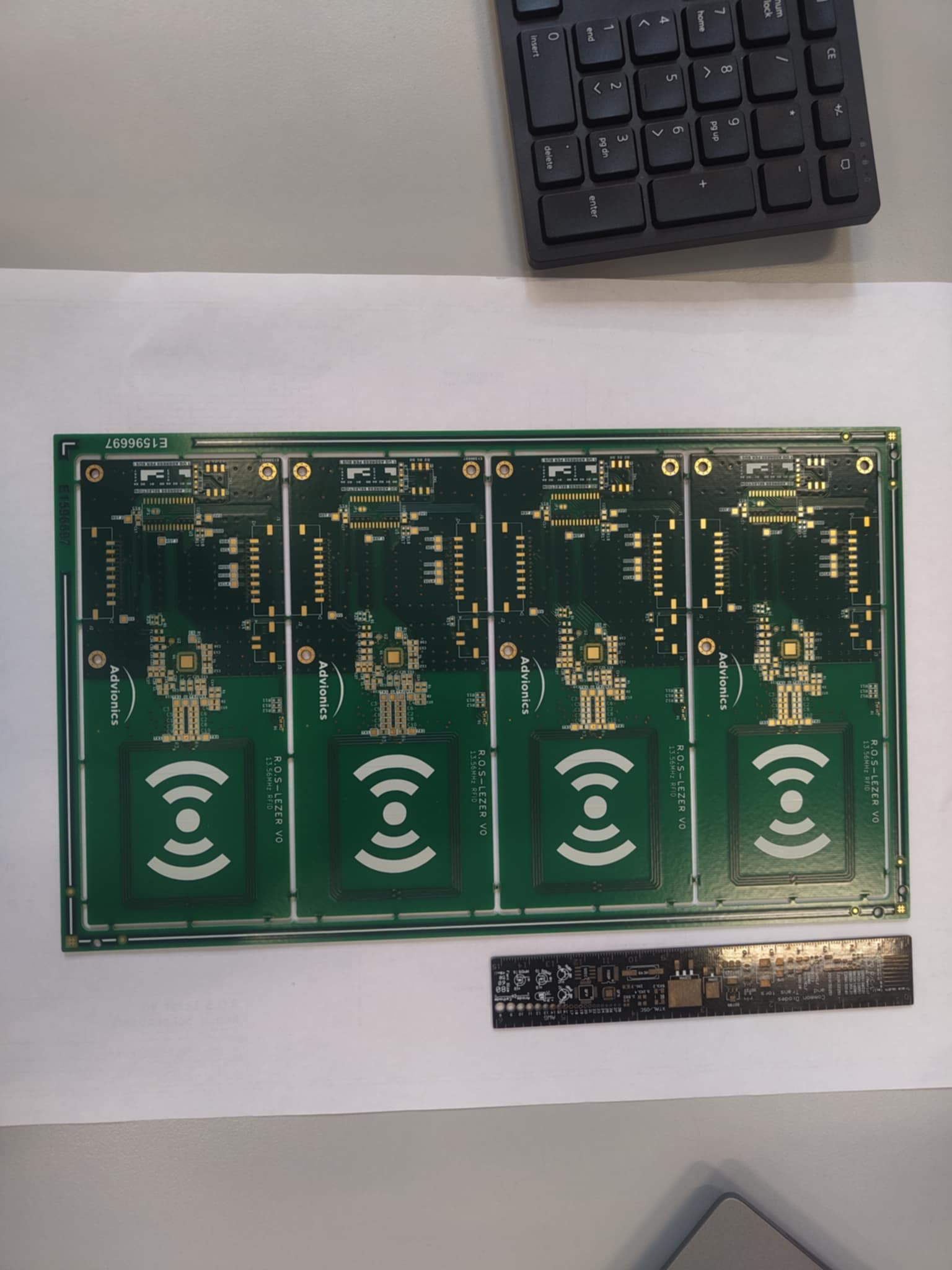

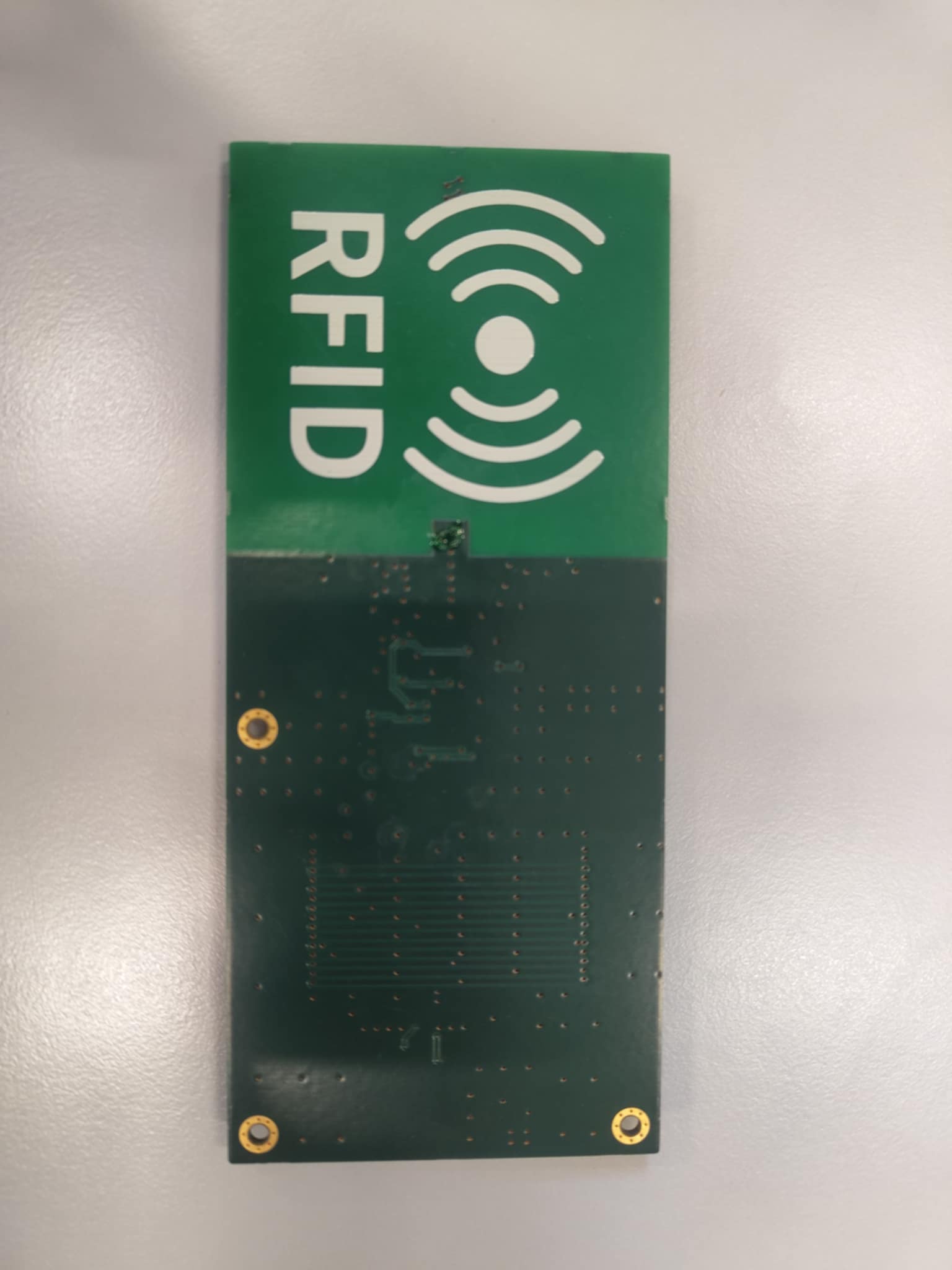

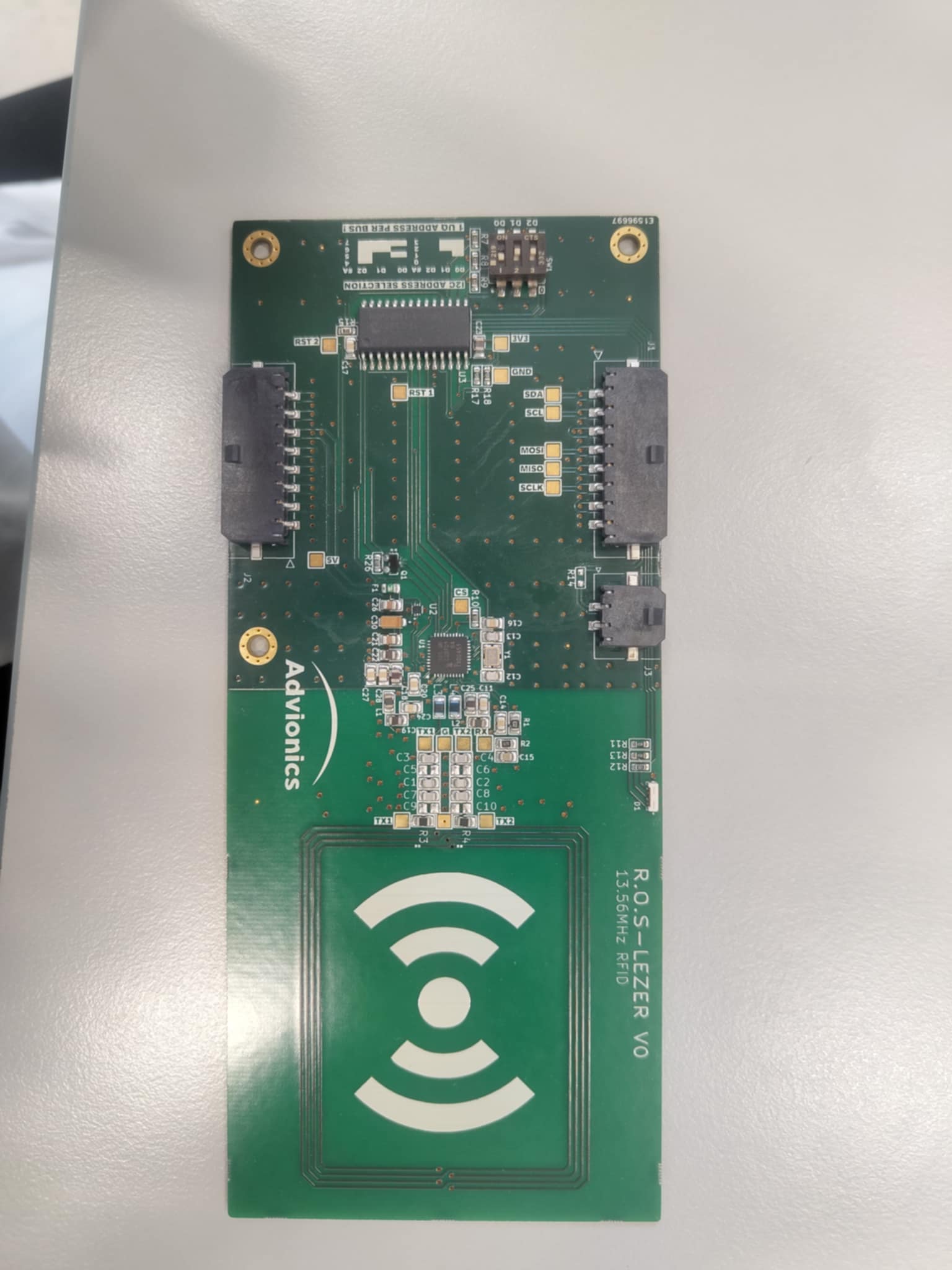

- NFC Reader Module: Each reader is built around the PN532 NFC chip, designed to read ISO 14443A/B tags at 13.56 MHz. The PCB includes an optimized antenna layout, a tri-state buffer system to prevent SPI bus conflicts, and an MCP23017 GPIO expander that allows addressable communication. Each reader features an RGB LED for feedback and an external LED connector for the locate function.

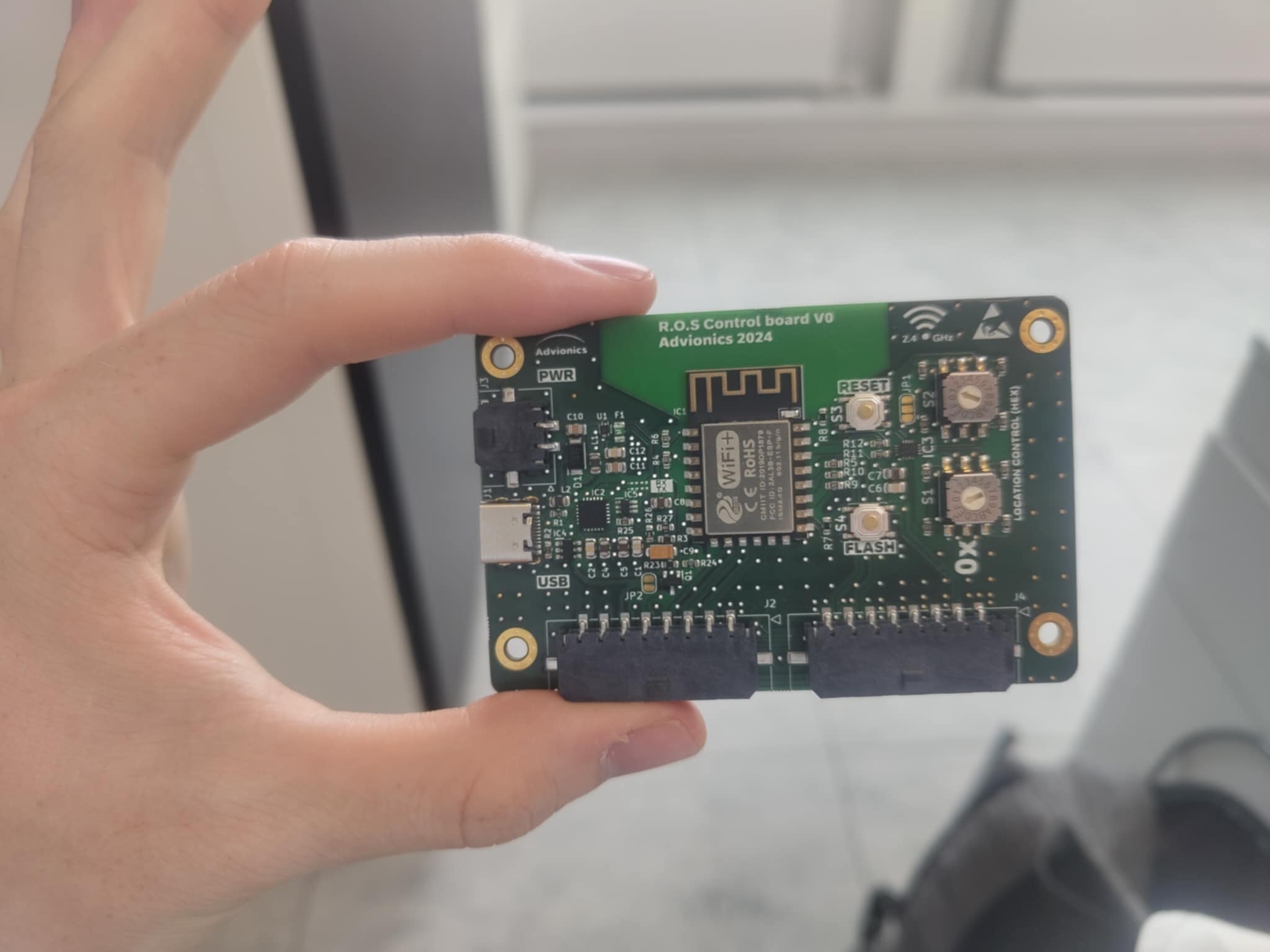

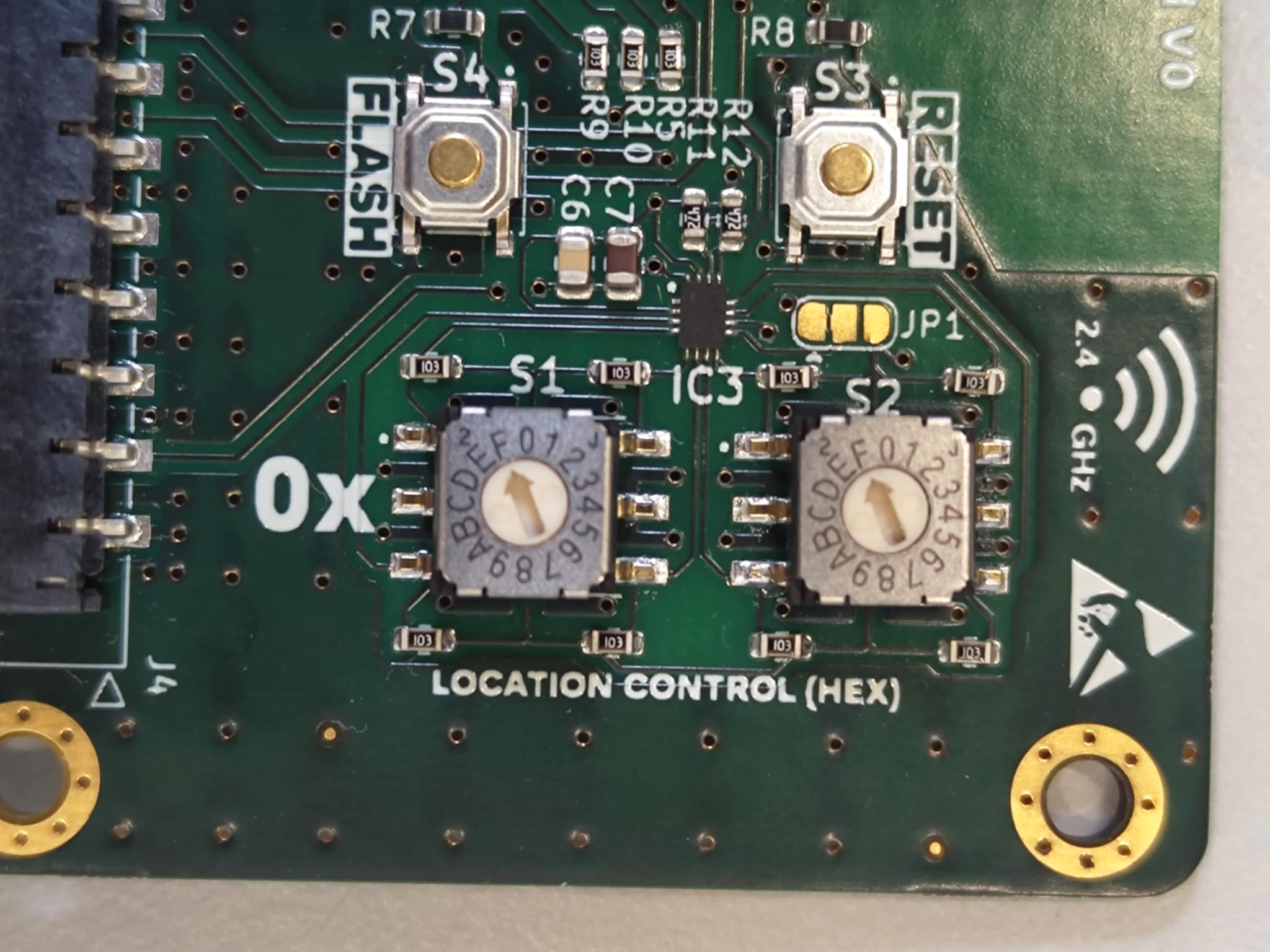

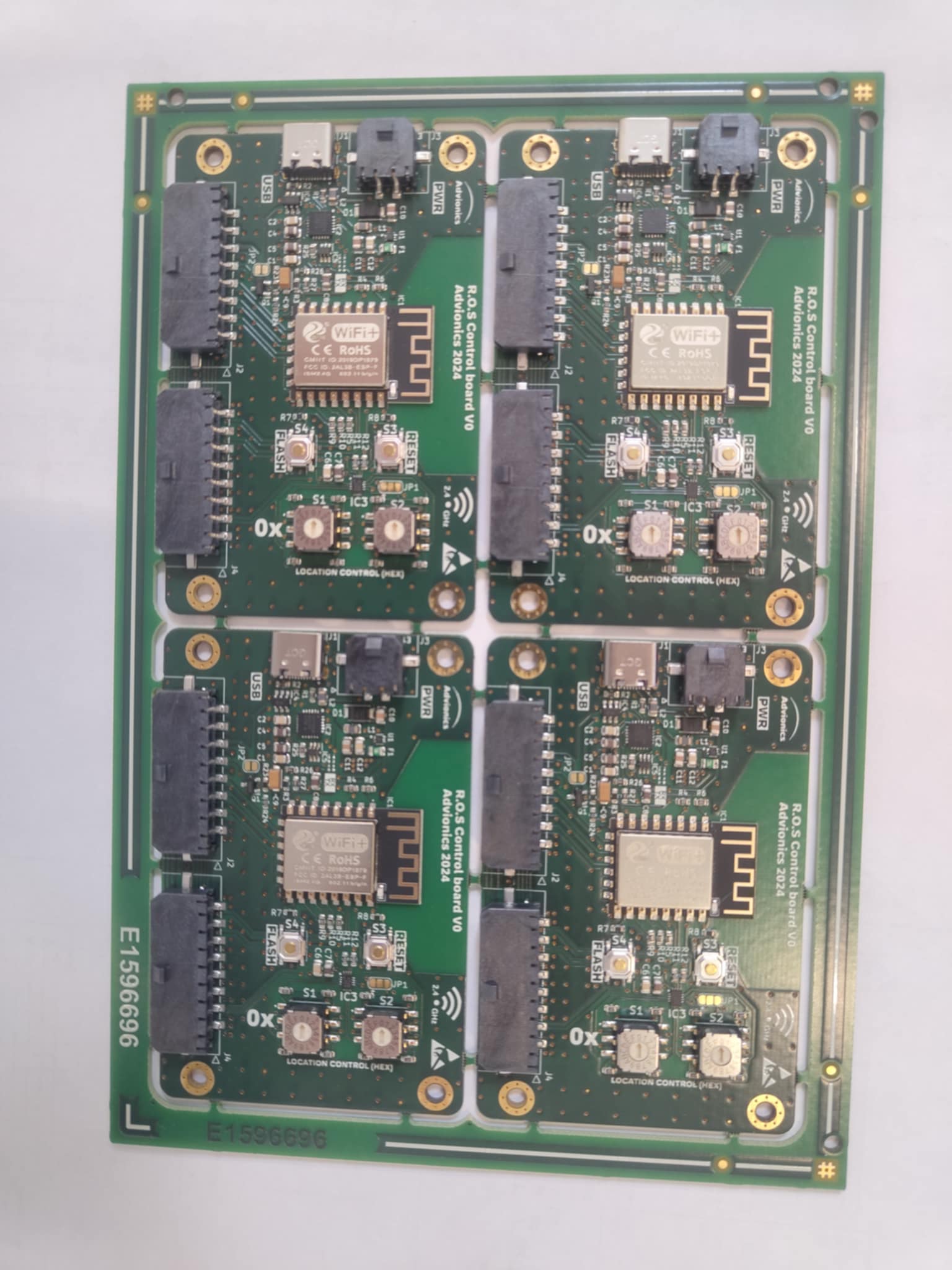

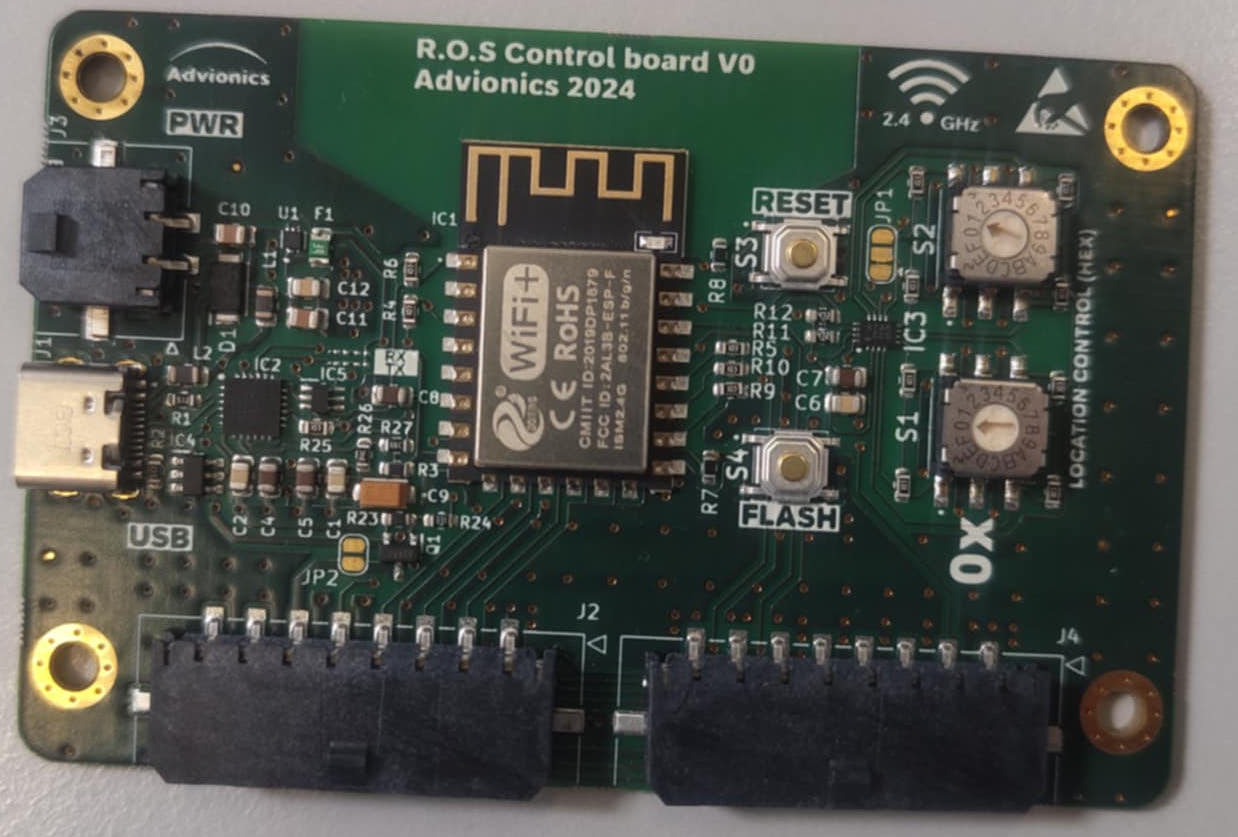

- Control Module: The heart of the system, based on an ESP8266 (ESP12E) microcontroller, manages communication with up to eight readers and transmits tag data to the server over Wi-Fi. It includes hardware power management (MOSFET switching), USB-C programming via a CP2101 interface, and location configuration using dual rotary DIP switches (hexadecimal location IDs).

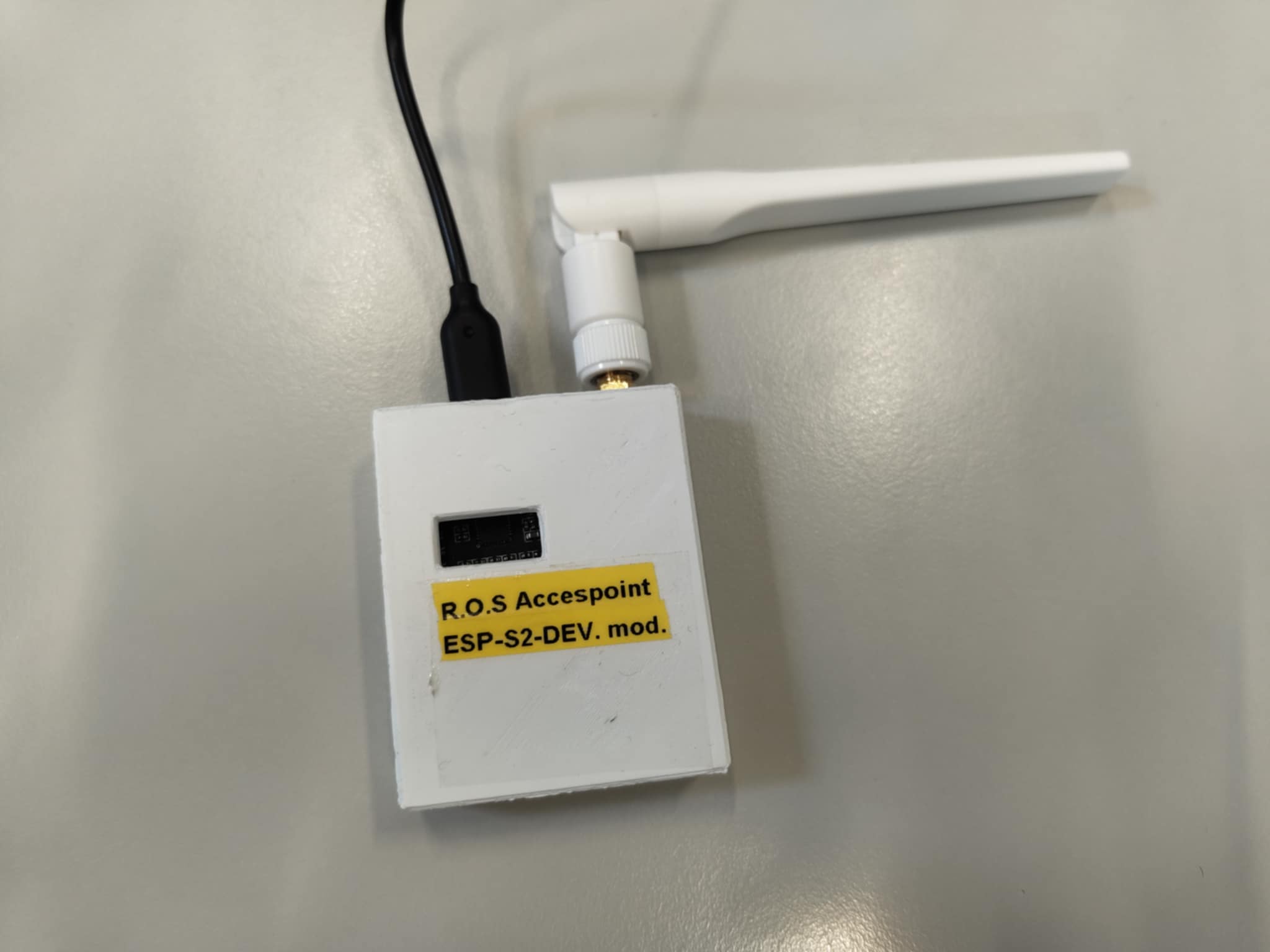

- Access Point: A dedicated ESP32-S2 board serves as a lightweight access point to aggregate data from multiple control modules, ensuring secure and stable communication. It uses a rotating SSID mechanism to handle more devices than standard Wi-Fi limits while maintaining encryption and hidden network identifiers.

- Backend: The backend runs on a Raspberry Pi configured with Apache and MariaDB/MySQL. It manages all data storage, NFC tag associations, and LED control commands through a REST-like PHP API. The database schema links NFC UIDs to product serial numbers and location IDs, allowing flexible tracking and reporting.

- Frontend: A responsive web dashboard built with HTML, CSS, JavaScript (jQuery), and PHP. It provides searchable tables, sorting and filtering tools, and real-time updates via asynchronous requests. Users can view the full item map, export data to PDF, or trigger LED indicators on specific readers directly from the browser.

Features

- Automated Tracking: Continuous NFC scanning updates item locations in real-time.

- Central Database Visualization: Web dashboard displays all items, locations, and statuses at a glance.

- LED “Locate” Function: Web-triggered LEDs help staff instantly identify and retrieve tagged items.

- Scalable & Modular Design: One control board supports up to eight readers; new locations can be added easily.

- Robust Communication: Wi-Fi connectivity secured with WPA encryption and lightweight XOR data obfuscation.

- Custom Hardware: Fully designed PCBs with ESD protection, PPTC fuses, and optimized NFC antenna geometry.

- Cross-Platform Interface: Accessible on desktop or mobile devices over the local network.

- Low-Cost Implementation: Total per-location cost under €700 in prototype stage, optimized for scaling.

Project Gallery